Strand loading, cutting and alignment system consisting of:

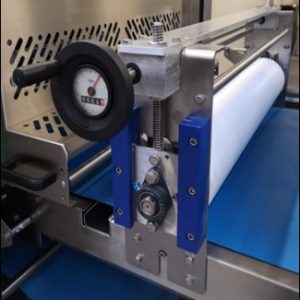

Automatic cutter with continuous blades

- Industrial continuous blade cutter for production

- Cutting head with continuous blades mounted on two ground and balanced rollers for perfect adherence of the blades to the surface of the rollers, one idle and and the other motorized. Tilting roller carrier beam , for better definition of bread cutting ;

- 12-mm blade pitch;

- Tungsten carbide blade-guiding hammers with envy coating

- Infeed belt , with adjustable guide rails, feed speed adjustable by a Siemens brand inverter motorvariator;

- Upper belt suitable for pushing bread to the blades, adjustable passage height;

- Stainless steel outlet chute;Machine needing airiacompressed;

- Machine made of painted steel, anodized aluminum, and stainless steel contact parts. CE-compliant guards and safety devices located at various points of the machine.

- Installed power 9Kw

- Air consumption : from 0 to about 300liters/minute

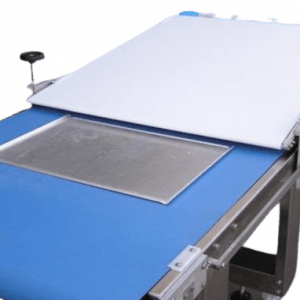

Elevating conveyor belt, suitable for receiving freshly cut slices of baguettes coming out of the cutters and transporting them over the vibrating table top unit; Facilitated unloading with steel chute

Vibrating platens group, designed to receive the cut baguette slices coming out of the cutter and by means of a series of motors with vibrating supports , we are going to divide the slices and lay them out , and then go to unload them always in random but not overlapping; Independent vibrating platens with independent motors group for each belt plane.

Full details and description on request