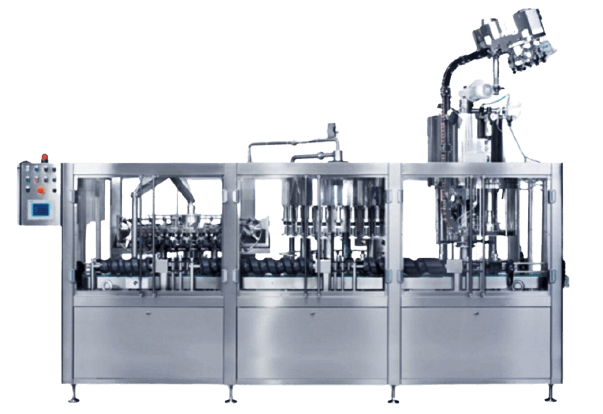

Juice packaging system

Plant consisting of 16-spout gravity filling machine and capping machine for plastic screw caps. The bottles are placed in the rotating loading lung, conveyed by conveyor belt to the monoblock, here the selection and transfer of bottles is done by auger. In the first station there are 16-gripper blowers, each bottle is treated individually with sterile air. They then go to the filling station, where the bottles are lifted, with plates equipped with a centering system, and the nozzle enters the container. Dosing taps are made of stainless steel with heat-sanitizable seals. Once filled, the bottles arrive in the automatic three-head screw cap capping machine. Cap loading is automatic.

Output: about 80-100 pcs/min. for 250 cc bottles

Full details and description on request.